Autoelectro Highlights Two Common Starter Motor ‘Underlying Issues’

Autoelectro has reiterated its technical pedigree in Rotating Electrics by providing valuable insights into potential issues that can arise from specific Starter Motors.

For almost 40 years, the remanufacturer has supported the automotive aftermarket, providing motor factors and technicians alike with a quality, OE-specification product.

As part of this commitment and longevity in the trade, not only does Autoelectro supply a reliable product, but it provides fantastic aftersales support. This is possible, thanks to the technical nous of its engineers, some of whom have worked for the family-run business for more than 30 years.

This information has been gained by stripping back old cores or inspecting damaged components at its remanufacturing facility in Bradford. Autoelectro is keen to share this knowledge to reduce returns – frustrating and, potentially, damaging for both motor factors and technicians’ reputations.

Diagnose and repair – don’t just replace!

It is important to stress that these two issues have arisen from underlying vehicle faults, rather than the Starter Motor itself. Autoelectro urges technicians to diagnose and cure the problem, rather than simply replace the ‘broken’ unit.

Autoelectro’s Harnek Bhogal believes the philosophy of simply changing the unit is problematic for the entire supply chain – he explained: “If a motor factor simply accepts the return and sends another Starter, without a technician investigating the underlying issue, it can lead to misunderstandings and annoyance.

“The technician could assume the factor is supplying low-quality parts, while the motorist may lose confidence in the technician. Ultimately, no one benefits from this approach.”

Furthermore, Autoelectro encourages technicians to always investigate the broader electrical system before installing a new Starter Motor. Taking this extra step should ensure a long-lasting repair, prevent comebacks and maintain trust between motor factors, technicians and motorists.

Common Starter Motor issues

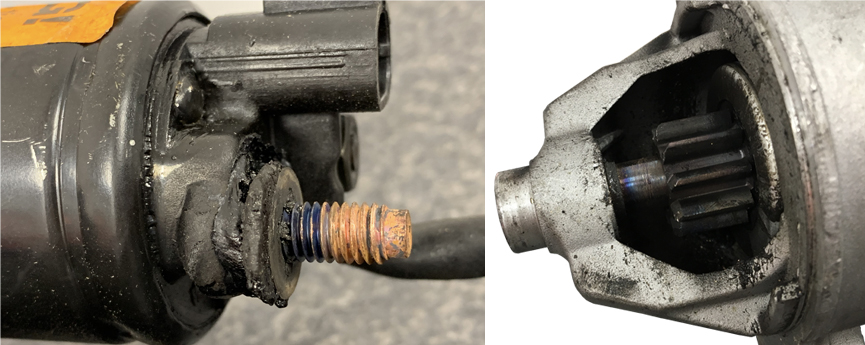

AEY2803: Vauxhall Antara, Chevrolet Cruze/Captiva 2.0-2.2 models (2009-onwards)

Autoelectro has observed the wiring loom to the rear of this Starter Motor solenoid is not always heat shrunk correctly. Consequently, the solenoid’s B+ terminal is prone to melting off due to excessive heat exposure. Without addressing this wiring issue, replacing the Starter Motor alone will not provide a lasting fix.

AEY3906: Dacia Sandero/Duster, Renault Clio, Nissan Micra 0.9-1.2 models (2013 onwards)

Sometimes, vehicles equipped with a push-button start can experience a fault where the button becomes stuck, keeping the Starter motor engaged. When this happens for an extended period, the Starter’s internal components overheat and fail – a condition known as a ‘burnt out’ starter. Again, replacing the Starter without fixing the faulty button mechanism will only lead to repeated failures.

It is important to remember that a starter motor does not produce power on its own; it relies on a vehicle’s ignition system, battery and wiring. As a result, if a Starter Motor has failed, to reiterate, it is probable that an underlying vehicle fault is responsible.

Harnek added: “Unfortunately, the two aforementioned issues are common, but, reassuringly, we pack these types of technical notes inside the boxes. Furthermore, this information is available on our website, plus customers can send photos to our popular WhatsApp support number.”

By providing these valuable insights, made possible thanks to Autoelectro’s team of knowledgeable and experienced engineers, the remanufacturer of starter motor and alternators is able to come to the aid of the automotive aftermarket – as it has done for 39 years.