Autoelectro Premieres its ‘Behind the Scenes’ Video Online

Posted On: 25th June 2018

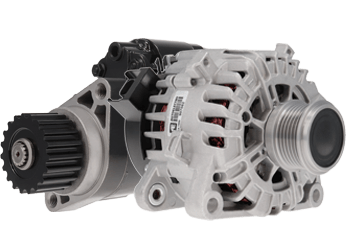

Autoelectro is pleased to release its new ‘behind the scenes’ video, filmed at its Bradford headquarters and remanufacturing facility, that illustrates the company’s journey to becoming the UK’s largest independent remanufacturer and supplier of starter motors and alternators.

Within the two-and-a-half-minute video is a comprehensive guide to the remanufacturing process, from stripping down the old core all the way through to packaging and distributing the remanufactured component in Autoelectro’s bright red box.

Managing Director, Tony Bhogal, provides an insightful commentary and is the man in-front of the camera. He explains how the business has developed over three decades, which includes an emphasis on product development, technical information and recruiting expert auto-electricians and fuel injection engineers. He also clears up any confusion between remanufacturing and reconditioning.

Tony said: “I was proud to let in the cameras into our home and showcase a warehouse that continues to expand and homes some of the best remanufacturing and testing equipment. Our family of staff members buy into our business philosophy of ‘fit and forget’, which allows us to produce and distribute quality products and fulfil a 100% order rate.

“We have more than 4,000 individual references that cover more than 100,000 applications, with a guarantee of meeting or exceeding original equipment specifications.”

“Our recent ISO standard reaccreditation strengthens our position in the marketplace, and our doors are always open to those that want to visit a professional and efficient company on top of its game.”

Check out the video below:

*Original article can be found in the IAAF Newsletter and on their website at: www.iaaf.co.uk/news-item/autoelectro-premieres-its-behind-the-scenes-video-online/.

Want to see more?

You can now Become a Distributor and access Product Price & Availability, 360° Rotating Product Images and much more via your own Account Dashboard!

If you already have an account with us click here to log in.

Search

Recent Posts

Archives

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- October 2017

- August 2016

- July 2016

- May 2016

- November 2015

- April 2014

Find Your Vehicle

Contact Us

-

Nirmalec House

848 Leeds Road,

Bradford,

West Yorkshire,

BD3 9TU - Opening Times: Mon - Fri: 08:00 - 17:00

- Email: sales@autoelectro.co.uk

- Tel: +44(0)1274 656101 *

- WhatsApp: +44(0)7972 804336

Useful Links

* Calls are recorded for training and quality purposes

This websites use cookies. By continuing to browse the site you are agreeing to our use of cookies.